Top 10 OSHA Violations of 2024: Insights & Solutions for a Safer Workplace

Each year, OSHA unveils the Top 10 Safety Violations. This list highlights the most common areas where companies fall short of compliance, shedding light on the persistent hazards that put workers at risk.

For businesses across industries, understanding these violations is key to building safer workplaces, avoiding penalties, and protecting employees. With the 2024 list now available, let's explore the most frequently cited violations and how they impact the safety landscape.

1. Fall Protection – General Requirements (1926.501) – 6,307 Violations

For the 14th year in a row, fall protection tops OSHA’s list with over 6,000 violations. Falls continue to be a leading cause of serious work-related injuries and fatalities, particularly in construction. This ongoing issue underscores the critical need for employers to enforce proper fall protection systems, equipment, and protocols in any environment where employees work at height.

2. Hazard Communication (1910.1200) – 2,888 Violations

Hazard communication covers the labeling, classification, and dissemination of information regarding hazardous chemicals. This violation continues to rank high because of the widespread use of chemicals in industries such as manufacturing, healthcare, and retail. Miscommunication or improper labeling can lead to serious accidents, including chemical burns, inhalation injuries, or worse. Employers must ensure proper labeling, up-to-date safety data sheets (SDS), and adequate employee training on the handling of hazardous substances.

3. Ladders (1926.1053) – 2,573 Violations

Improper ladder use is another common safety hazard, leading to thousands of violations every year. From failing to inspect ladders before use to not following proper procedures when climbing or descending, these errors can result in dangerous falls. Ladder-related accidents are not limited to construction but also occur in warehouses, retail environments, and other industries where employees need to reach elevated areas.

4. Respiratory Protection (1910.134) – 2,859 Violations

Respiratory protection violations occur when employers fail to provide adequate protection to workers exposed to harmful dust, vapors, or other airborne contaminants. This violation can be particularly dangerous in environments like construction, manufacturing, and chemical processing, where exposure to respiratory hazards is common. A lack of proper respiratory protection can result in long-term health issues, including respiratory illnesses and occupational asthma.

5. Lockout/Tagout (1910.147) – 2,443 Violations

Lockout/Tagout (LOTO) procedures are essential for preventing the accidental release of hazardous energy when servicing equipment. Unfortunately, many companies fail to properly implement or enforce these procedures, leading to serious injuries and even fatalities. LOTO violations often occur in manufacturing environments, where workers may be unaware that equipment is still powered on, resulting in accidental startup and potentially life-threatening accidents.

6. Powered Industrial Trucks (1910.178) – 2,248 Violations

Forklifts and other powered industrial trucks are essential in industries like warehousing, manufacturing, and retail, but they also pose significant risks. OSHA frequently cites violations related to improper operation, maintenance, and training. These vehicles can cause accidents such as collisions, tip-overs, or worker injuries if not used correctly, making it crucial for employers to ensure proper training and safe operating procedures.

7. Fall Protection – Training Requirements (1926.503) – 2,050 Violations

Training plays a critical role in fall protection, and failure to provide adequate training to employees contributes to thousands of violations each year. OSHA requires that workers not only have access to fall protection equipment but also understand how to use it correctly. Lack of training increases the likelihood of accidents, as employees may misuse equipment or fail to recognize hazards, leading to preventable falls.

8. Scaffolding (1926.451) – 1,873 Violations

Scaffolding violations often stem from improper assembly, lack of fall protection, and inadequate safety measures. In construction and maintenance work, scaffolding is frequently used, but if it is not set up correctly or safety precautions are ignored, it becomes a significant hazard. Workers must be trained to assemble, inspect, and work on scaffolding safely to reduce the risk of accidents.

9. Personal Protective and Lifesaving Equipment – Eye and Face Protection (1926.102) – 1,814 Violations

Eye and face protection violations are common in industries where workers are exposed to flying debris, chemicals, or hazardous materials. Despite the risks, many workers fail to wear the appropriate protective gear, leading to preventable injuries. OSHA requires employers to provide adequate eye and face protection to workers in hazardous environments and to enforce its use.

10. Machine Guarding (1910.212) – 1,541 Violations

Machine guarding violations occur when machines are not equipped with the necessary guards to protect workers from dangerous moving parts. These violations are prevalent in manufacturing environments, where unguarded machinery can cause serious injuries such as amputations or crushing injuries. OSHA requires that all machinery with moving parts be properly guarded to prevent accidental contact with workers.

The Importance of OSHA Compliance

The Top 10 OSHA Violations list serves as a stark reminder of the importance of maintaining compliance with safety standards to keep your employees safe from harm. These violations are not only costly in terms of fines and potential litigation but also result in preventable injuries and fatalities. For businesses, understanding the most common violations and addressing them proactively is essential to protecting employees and maintaining a safe workplace.

By focusing on training, proper equipment use, and regular safety inspections, companies can significantly reduce the risk of these violations. Safety is an ongoing commitment, and staying informed about current risks and best practices is crucial for any organization that values the well-being of its workers.

Take Action to Keep Your Workplace Safe

Staying compliant with OSHA regulations is critical to protecting your employees and maintaining a safe work environment. Whether you're looking to update your safety protocols or ensure your workplace meets current standards, taking proactive steps can help prevent these common violations.

Understanding OSHA Violations in Industrial Settings

OSHA violations occur when workplace safety standards aren't properly maintained. These violations can range from minor infractions to serious safety hazards that put workers at risk. Understanding common violation categories helps facilities develop comprehensive safety programs.

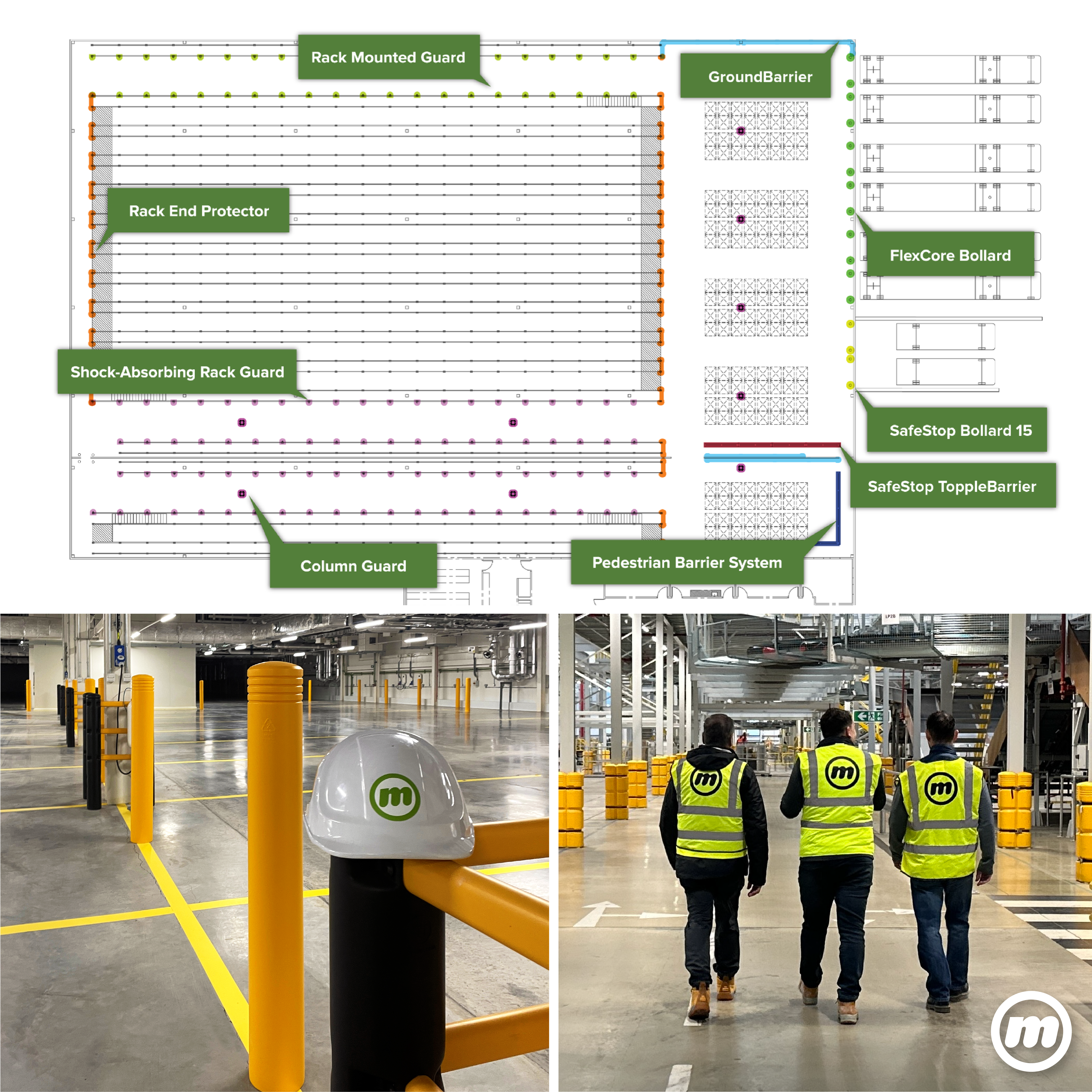

The Role of Physical Barriers in Compliance

Physical safety barriers play a crucial role in addressing multiple OSHA compliance areas. Strategic barrier placement helps facilities maintain safe working conditions by:- Creating physical separation between workers and hazards

- Defining safe walkways and operational zones

- Preventing unauthorized access to dangerous areas

Protecting equipment and structural elements

Proactive Safety Management

Successful OSHA compliance requires ongoing attention to workplace safety. Regular safety assessments identify potential violation areas before they become citations. This proactive approach to safety management benefits facilities through improved worker protection and operational efficiency.

How Safety Infrastructure Supports Compliance

Modern safety infrastructure goes beyond basic compliance requirements. Well-designed safety systems create environments where safe practices become standard operating procedure. This includes proper barrier systems, clear visual indicators, and defined traffic patterns that reduce accident risks.

McCue's safety solutions support facilities in maintaining OSHA compliance through strategic placement of protective barriers and comprehensive safety assessments.

Addressing Safety Hazards Through Systematic Approaches

Identifying and Controlling Recognized Hazards

Recognized hazards in workplace environments require systematic identification and control measures. These safety hazards exist across all industries, from manufacturing floors to office settings. Effective hazard recognition involves regular workplace assessments, employee feedback, and documentation of potential risks.

The Connection Between Violations and Workplace Accidents

When safety hazards go unaddressed, they often result in both OSHA violations and workplace accidents. Personal protective equipment failures, inadequate fall protection systems, and exposed hazardous energy sources represent common areas where violations occur. Understanding these connections helps facilities prioritize safety improvements.

Occupational Safety as a Management Priority

Occupational safety extends beyond compliance checkboxes. It requires leadership commitment, resource allocation, and continuous improvement. Facilities that prioritize occupational safety typically see fewer violations, reduced accident rates, and improved operational efficiency.

Control of Hazardous Energy in Modern Facilities

The control of hazardous energy remains critical across industries. Beyond traditional lockout/tagout procedures, modern facilities must address multiple energy sources including electrical, mechanical, hydraulic, and pneumatic systems. Proper energy control prevents serious physical harm to workers during maintenance and servicing operations.

Preventing Serious Physical Harm Through Engineering Controls

Engineering controls provide the first line of defense against serious physical harm. These include physical barriers, safety interlocks, and automated shutoff systems. When properly implemented, engineering controls reduce reliance on personal protective equipment alone and create inherently safer work environments.

The Role of Powered Industrial Trucks in Workplace Safety

Powered industrial trucks present unique challenges in maintaining workplace safety. These vehicles operate in close proximity to pedestrians, storage systems, and facility infrastructure. Strategic safety measures, including designated travel lanes, physical barriers, and visibility enhancements, help prevent accidents involving powered industrial trucks.

Conclusion: How McCue Plays a Role in Mitigating OSHA Violations

At McCue, we recognize that these statistics are not just numbers—they represent real-world risks that workers face every day. Our range of industrial safety barriers and protection solutions are designed to address these hazards head-on, helping your facility stay compliant with OSHA standards and safeguarding your most valuable asset—your people. From people protection to facility protection and rack protection, our products are engineered with the highest safety standards in mind.

Ready to take the next step?

Meet with one of our safety experts today to learn how McCue can help you keep your people safe, stay compliant, and safeguard your facility. Request a consultation here.